페이지 정보

본문

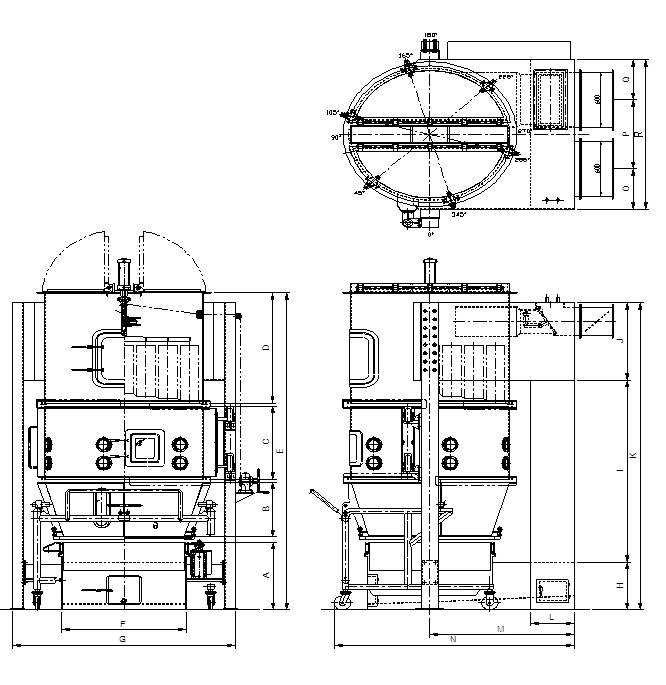

G series

SOLID DOSE > Fluid bed processor

The powder in the sealed container are moved in all direction and dried when they are exposed to hot air heated by the steam heater : the granulated material(porous) is formed and dried as the result of condensation between particles when the binder solution is sprayed through the spray nozzle.

The Machine is used for such purposes as mixing granulating, and drying.

The explosion due to static-electricity is prevented using a special bag filter.

Since all the processes are carried out in a sealed container, hygiene related problems do not occur. Also, cGMP regulations are satisfied.

The disadvantages of solenoid valve are improved by using a pneumatic type steam control valve.

Maximum safety of the machine is ensured with the installation of a relief flap for explosion.

| ◆ Principle of Fluid Bed Process |

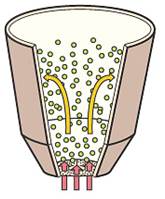

1. Fluid Bed dryer

| ◆ Types and application of fluid bed process temperature. It is by application of basic principle and structure of fluid bed.

◆ Application

◆ Types of fluid bed process |

2. Top Spray Fluid Granulator

| - By installing spray nozzle at upper part of fluid bed granulation and coating are performed. - Granulation of minute powder particle and adsorption of solution.

◆ Characteristics |

◆ Prevention of pollution

It has a structure whereby products can be flowed and in the process being dried and granulated and it completely eliminated any possibility of pollution from machinery.

Also it has a design whereby washing liquid at the time of washing is easily discharged through discharge port.

| ◆ Convenience of work at fluid part

◆ Hot wind generating device (Pre + Medium + HEPA + Medium) |

◆ Installing and removing bag filter

For installing and removing bag filter wire rope method is adopted thus at the time of work safety and convenience are considered in its design and at the time of installing

and removing by mounting automatically locking device safety and convenience of worker are considered in its design.

◆ Feeding pump

Feeding pump is flow amount control interlocking pump and always a certain amount is flowed into spray nozzle and its material is silicon which does not corrode even by

organic urea and halogen liquid and a certain specified quantity can be emitted in spite of variable viscosity and change in temperature.

| ◆ Container lifter inspected inside of fluid granulation dryer and causing pollution are completed eliminated. |

| ◆ Spray nozzle - Nozzle is designed to circulate always without sedimentation or dissolution of spray solution |

◆ Binder tank

Heater(Choice of steam and electric) and agitator(Choice of prevention of sedimentation and for dissolving) are installed for maintaining temperature and prevention

of sedimentation and for dissolution in order to maintain best condition at the time of spraying.

◆ Control part

It is divided into air control panel and electric panel. So it can be used safety in the area belongs to explosion range and is made to assure checking process at a glance.

In particular P.L.C. is used to expedite convenient application under different circumstances.

|

|

- NextOPTIONS-KSPL(PN)- 50 25.07.31